Components of a VFD Control Panel

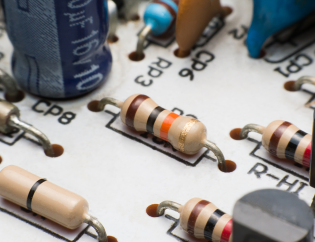

A VFD Control Panel typically contains three main components:

- Power Section: This section includes the power components required to supply the VFD and the motor with the necessary voltage and current. This includes transformers, fuses, circuit breakers, contactors, and other electrical components.

- Control Section: This section houses the control components that communicate with the VFD and allow the user to set the motor speed, direction, and other parameters. This includes programmable logic controllers (PLCs), human-machine interfaces (HMIs), and other control devices.

- Communication Section: This section provides the necessary communication interfaces to allow the VFD Control Panel to connect to other devices in the system. This includes Ethernet, RS-485, and other communication protocols.

Benefits of VFD Control Panels

There are many benefits to using a VFD Control Panel for your industrial equipment. Here are a few of the most common benefits:

Energy Savings:

By controlling the speed of the motor, a VFD Control Panel can reduce energy consumption, saving you money on your electricity bill. The VFD can adjust the motor speed based on the load, which means that the motor only uses the energy required to do the job rather than running at a fixed speed all the time.

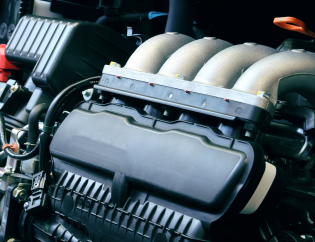

Reduced Wear and Tear:

By starting and stopping the motor smoothly and controlling the speed, a VFD Control Panel can minimize wear and tear on the engine, extending its lifespan and reducing maintenance costs. Without a VFD Control Panel, motors are typically started with a sudden surge of power, which can cause mechanical stress and wear and tear.

Improved Process Control:

By regulating the speed of the motor, a VFD Control Panel can improve the accuracy and consistency of your process, which can help you produce higher quality products. With a VFD Control Panel, you can precisely set the speed of the motor, which means that you can control the process more accurately.

Don’t settle for inefficient industrial operations. Invest in ECSKSA’s VFD solutions to improve your energy efficiency, process control, and equipment lifespan.

Applications of VFD Control Panels

VFD Control Panels are commonly used in a variety of applications, including:

HVAC Systems:

VFD Control Panels are commonly used to regulate the speed of HVAC (Heating, Ventilation, and Air Conditioning) systems. By adjusting the speed of the fan or blower motor, the VFD Control Panel can help regulate the temperature and humidity in a building while also reducing energy consumption.

Pump Systems:

VFD Control Panels are commonly used in pump systems, such as water treatment plants and irrigation systems. By adjusting the speed of the pump motor, the VFD Control Panel can help maintain a constant flow rate, improving process efficiency and reducing energy consumption.

Conveyor Systems:

VFD Control Panels are also used in conveyor systems, such as manufacturing and warehouse facilities. By adjusting the speed of the conveyor motor, the VFD Control Panel can help regulate the flow of products, which can improve process efficiency and reduce energy consumption.

Industrial Equipment:

VFD Control Panels are commonly used to regulate the speed of other industrial equipment, such as mixers, agitators, and extruders. By adjusting the speed of the equipment motor, the VFD Control Panel can help improve process control and reduce energy consumption.

Choosing the Right VFD Control Panel

When selecting a VFD Control Panel for your facility, several factors must be considered. Here are a few things to keep in mind:

- Motor Type and Size: The VFD Control Panel must be compatible with the type and size of the motor being controlled. Make sure to select a panel rated for your motor’s voltage and current requirements.

- Control Options: Consider the control options available on the VFD Control Panel. Some panels may include basic controls, while others may include advanced options like remote monitoring and control.

- Environmental Factors: Consider the environment in which the VFD Control Panel will be installed. If the panel is exposed to extreme temperatures or humidity, make sure to select a panel that is rated for those conditions.

- Service and Support: Consider the availability of service and support for the VFD Control Panel. Select a panel from a reputable manufacturer that offers technical support and spare parts.

Conclusion

A VFD Control Panel is an essential tool for regulating the speed of electric motors in industrial settings. It can help reduce energy consumption, improve process control, and increase equipment lifespan. By understanding the components of a VFD Control Panel, the benefits of using one, and how to choose the right one for your facility, you can ensure that your equipment runs at optimal levels, which can help you save money and improve efficiency.

Are you looking for a reliable and customizable VFD motor control panel for your industrial facility? Look no further than our top-quality VFD Control Panels. With our expert engineering and tailored solutions, we can provide you with a VFD Control Panel that meets your specific needs and improves your equipment’s efficiency. Contact us today to learn more about how we can help you optimize your operations with our VFD Control Panels.

Do you have a question in your mind? If so, make sure to fill out the form below!