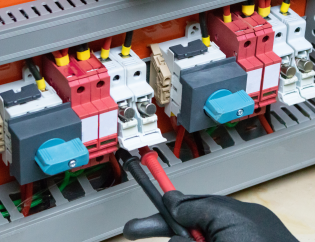

Components of Switchgear:

Electrical switchgear combines electrical components, including circuit breakers, fuses, switches, and relays, designed to control, protect, and isolate electrical circuits and equipment. Switchgear is commonly used in power generation, transmission, and distribution systems, as well as in industrial and commercial facilities. The primary components of switchgear include:

- Circuit breakers: These are devices that are used to interrupt or break an electrical circuit when a fault occurs. They protect electrical equipment from damage due to overcurrent, short circuits, and other electrical faults.

- Fuses: These are devices that are used to protect electrical equipment from overcurrents. When a current higher than the rated value flows through a fuse, it melts, opening the circuit and preventing damage to the equipment.

- Isolators: These are devices that are used to provide isolation between electrical equipment. They allow maintenance work to be carried out safely by isolating the equipment from the power supply.

- Switches: These are devices that are used to open and close an electrical circuit manually. They are often used for control purposes.

- Transformers: These are devices that are used to step up or step down the voltage of an electrical supply. They are often used in switchgear to supply power to different parts of the power system.

- Busbars: These are conductors that are used to connect different components of the switchgear together.

- Relays: These are devices that are used to detect faults in the power system and to initiate the opening of a circuit breaker.

All of these components work together to ensure the safe and efficient operation of the power system.

Switchgear Failure Modes:

Switchgear failures can occur due to a variety of factors, and it is essential to understand the different modes of failure to prevent them from happening. Here are some of the most common switchgear failure modes:

Faulty Switchgear Connections:

Poorly connected switchgear components can cause many problems, including arcing, overheating, and component failure. Loose or corroded connections can cause high resistance, overheating, and damage components such as circuit breakers and busbars. High resistance can also result in arcing, which can cause insulation damage and increase the risk of fires.

Degraded Switchgear Insulation:

Insulation is critical in switchgear components to prevent arcing, electrical discharge, and other electrical breakdowns. Over time, insulation can degrade due to various factors, including heat, moisture, mechanical stress, and environmental factors. Degraded insulation can cause high resistance, arcing, and component failure.

Improper Switchgear Service:

Switchgear components require regular maintenance and service to ensure proper operation. Improper or inadequate service can lead to component failure, including circuit breakers, contactors, and fuses. Wrong service can also result in loose connections, insulation damage, and other problems that can cause switchgear failure.

Old Switchgear Components:

Switchgear components have a finite lifespan like any other electrical equipment. As components age, they can become less reliable, leading to increased risk of failure. Older switchgear components can also become obsolete, making it difficult to find replacement parts and increasing the risk of equipment failure.

Switchgear Water Intrusion:

Water intrusion can cause switchgear components to short-circuit and fail. Water can enter switchgear enclosures through cracks, leaks, or inadequate sealing. Moisture can cause insulation damage, corrosion, and other problems leading to switchgear failure.

Environmental Causes:

Switchgear failures can also occur due to environmental factors such as extreme temperatures, humidity, dust, and vibrations. Extreme temperatures can cause the expansion and contraction of switchgear components, leading to damage over time. Dust and other debris can accumulate on switchgear components, increasing the risk of arcing and component failure. Vibrations can cause loose connections, insulation damage, and other problems leading to switchgear failure.

By understanding the different modes of switchgear failure and taking appropriate preventative measures, we can ensure the safe and reliable operation of electrical power systems. If your switchgear components are outdated or showing signs of wear and tear, it may be time to consider an upgrade. Upgrading to newer, more reliable components can help prevent switchgear failures and ensure the safe and reliable operation of your electrical power system. Contact a qualified electrician at ECSKSA to discuss your options and determine the best course of action for your specific needs.

Avoiding Switchgear Failures:

To prevent switchgear failures, several steps can be taken to ensure the safe and reliable operation of electrical power systems. Here are some key measures to consider:

Regular Maintenance and Service:

Regular maintenance and service are critical to ensuring the proper operation of switchgear components. This includes cleaning enclosures, testing switchgear components for proper operation, and tightening connections. It is also essential to follow the manufacturer’s instructions and guidelines for maintenance and service.

Environmental Protection:

Environmental factors like moisture, dust, and extreme temperatures can cause switchgear failures. Protecting switchgear components from these factors can help prevent switchgear failures. This can include sealing switchgear enclosures to prevent moisture intrusion, providing proper ventilation to prevent overheating, and protecting switchgear components from dust and debris.

Proper Installation:

Proper installation of switchgear components is critical to preventing switchgear failures. It is essential to follow the manufacturer’s instructions and guidelines for installation, including ensuring that switchgear components are compatible with each other and with the electrical system they are part of.

Employee Training:

Proper training for personnel working with switchgear is crucial to prevent switchgear failures. Employees should be aware of the dangers associated with switchgear and understand the importance of following safety protocols. This includes de-energizing the switchgear before performing any maintenance or service work.

Contingency Planning:

In the event of a switchgear failure, having a contingency plan is crucial to ensure the continued operation of critical systems. This can include backup power sources or alternative power delivery methods to ensure that critical systems remain operational in the event of a switchgear failure.

These measures prevent switchgear failures, and the safe and reliable operation of electrical power systems can be ensured. Regular maintenance and service, protection from environmental factors, proper installation, employee training, and contingency planning are all critical components of an effective switchgear failure prevention plan.

Conclusion:

In conclusion, switchgear failures can be caused by various factors, including faulty connections, degraded insulation, improper service, old components, water intrusion, and environmental causes. Preventative measures, such as regular maintenance and service, protection from environmental factors, proper installation, and employee training, can help avoid switchgear failures. In case of a switchgear failure, having a contingency plan is crucial to ensure the continued operation of critical systems. By understanding the causes of switchgear failures and taking appropriate preventative measures, we can help ensure the safe and reliable operation of electrical power systems.

If you’re still unsure about how to prevent switchgear failures in your electrical power system, it may be helpful to consult with an expert. Contact ECSKSA now to discuss your concerns and receive guidance on the best practices for switchgear maintenance, operations and electrical care services,

Do you have a question in your mind? If so, make sure to fill out the form below!