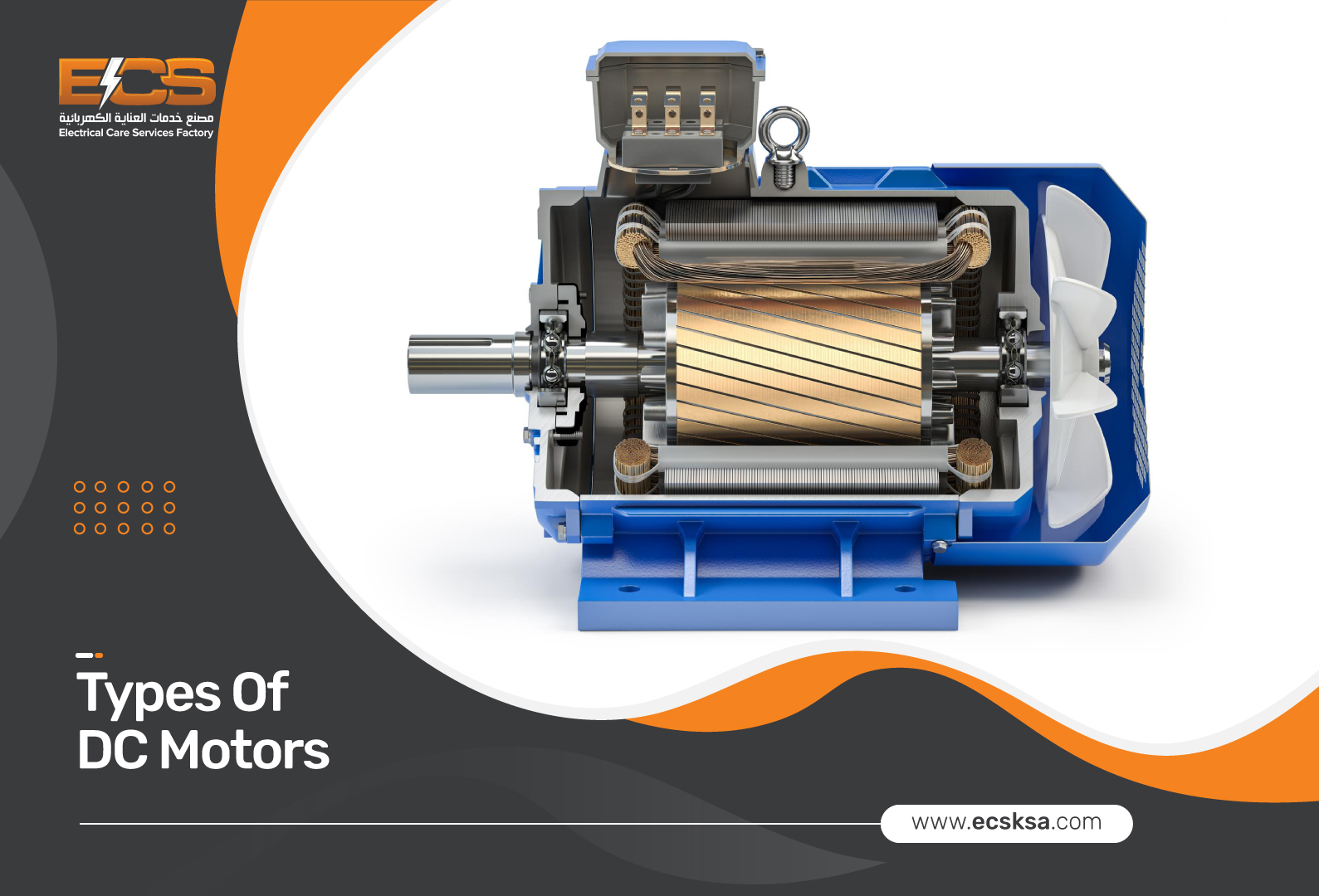

Introduction to DC Motors

A DC (Direct Current) motor is a device that converts electrical energy into mechanical energy. It works on the principle of electromagnetic induction, which states that when an electric current flows through a conductor in a magnetic field, a force is generated that causes the conductor to move. DC motors consist of a rotor (the rotating part) and a stator (the stationary part), with the rotor being the part that converts electrical energy into mechanical energy.

A DC motor operates based on the interaction between a magnetic field and an electric current. When a current flows through the stator, it creates a magnetic field that interacts with the magnetic field created by the rotor. This interaction causes the rotor to rotate, which, in turn, makes mechanical energy.

Types of DC Motors:

To better understand how to use DC motors for different purposes, it’s important to know the four main types of DC motors. Knowing this will help you choose the right one for your specific application.

Permanent Magnet DC Motors:

In permanent magnet DC motors, the stator has permanent magnets that provide the magnetic field, eliminating the need for a separate field winding. These motors are simple, efficient, and compact, making them ideal for applications that require a high power-to-weight ratio, such as electric vehicles, robotics, and drones.

Series-Wound Motors:

Series-wound motors have a field winding and an armature winding that is connected in series. These motors are designed to deliver high torque at low speeds, making them ideal for applications that require high starting torque, such as electric forklifts and cranes.

Shunt-Wound Motors:

Shunt-wound motors have a field winding and an armature winding that is connected in parallel. These motors are designed to provide consistent speed control, making them ideal for applications that require precise speed control, such as lathes and milling machines.

Compound DC Motors:

Compound DC motors are a combination of both series and shunt-wound motors. They have both a series field winding and a shunt field winding, allowing them to provide high starting torque and a constant speed. Compound motors can be classified into:

- Cumulative compound motors

- Differential compound motors

In cumulative compound motors, the series field winding is connected in such a way that it adds to the shunt field winding, increasing the motor’s torque. In differential compound motors, the series field winding is connected in a way that it subtracts from the shunt field winding, reducing the motor’s torque. Compound DC motors are used in applications requiring high starting torque and stable speed, such as heavy machinery, traction applications, and industrial equipment.

Upgrade your motor performance today! Contact us to discover the perfect motor control panels for your application and revolutionize the way you operate.

Uses of DC Motors:

DC motors are used in a wide range of applications across several industries. Some common uses of DC motors include:

- Electric Vehicles: DC motors are used in electric vehicles like electric cars, bicycles, and scooters.

- Industrial Machinery: DC motors are used in manufacturing equipment, conveyors, and material handling systems.

- HVAC Systems: DC motors are used in HVAC systems to control the airflows and temperature.

- Robotics: DC motors are used in robotics for precise movements.

- Aerospace: DC motors are used in aerospace applications to control various systems precisely.

Conclusion:

In conclusion, various types of DC motors are designed to meet specific industrial or commercial requirements. Series-wound DC motors provide high torque, while shunt-wound DC motors offer stable speed. Compound-wound DC motors combine the features of both series and shunt-wound motors, making them ideal for applications requiring high starting torque and constant speed. Permanent magnet DC motors are suitable for applications that require a high power-to-weight ratio, such as electric vehicles, robotics, and drones. By understanding the different types of DC motors and their unique features, engineers and electrical technicians can select the appropriate motor for their specific application, ensuring efficient and reliable performance.

Optimize your motor performance with ECSKSA’s expertly crafted motor control panels. Our customized solutions ensure maximum efficiency and reliability, tailored specifically to meet your industrial or commercial needs. Contact us today to learn more and take the first step towards enhanced motor control.

Do you have a question in your mind? If so, make sure to fill out the form below!