Visual Inspection

Exterior Inspection

- Enclosure: The first step in inspecting an MCC is to check the enclosure. Check for any signs of damage or corrosion on the MCC enclosure. Ensure the enclosure is properly grounded and all grounding connections are secure. Check that the enclosure is free from foreign objects that can interfere with the ventilation system.

- Doors and Covers: Inspect the doors and covers of the MCC for signs of wear, damage, or loose fasteners. Ensure that all locks and latches function correctly and that the doors and covers seal properly. Inspect the gaskets on the doors and covers to ensure they are in good condition.

- Labels and Nameplates: Check that all labels and nameplates are in place and legible. Ensure that they are accurate and reflect the current configuration of the MCC. Check for any missing or faded labels.

Interior Inspection

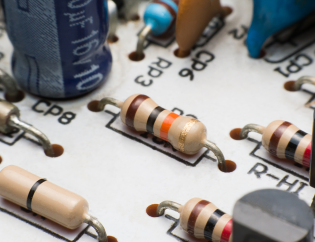

- Wiring: Inspect all wiring for signs of wear, damage, or loose connections. Ensure that all wiring is labeled correctly and that there are no signs of overheating or melting. Check for any signs of rubbing or abrasion on the wires.

- Circuit Breakers: Check that all circuit breakers are correctly seated, and the connections are tight. Ensure that the trip settings are correct and there are no overheating signs. Check for any signs of corrosion or damage on the circuit breakers.

- Fuses: Inspect all fuses for signs of damage or wear. Ensure that the correct size and type of fuse are installed. Check for any signs of overheating or blackening around the fuse.

- Contactors: Check that all contactors function correctly and that the contacts are clean and properly aligned. Ensure that the contactor coils are properly energized and there are no overheating signs. Inspect the contactors for any signs of wear or damage.

- Overload Relays: Inspect all overload relays for signs of wear or damage. Ensure that they are set to the correct trip point and that there are no signs of overheating. Check for any signs of corrosion or damage on the overload relays.

Electrical Testing

Voltage Testing

To ensure the proper functioning of an MCC, it is essential to test the voltage levels. Voltage testing can be performed using a voltmeter or a multimeter. Start by checking the voltage levels on the incoming power lines. Then, check the voltage levels on the individual circuit breakers to ensure they are within the acceptable range. Corrective action should be taken immediately if any voltage levels are outside of the acceptable range.

Current Testing

Current testing can be performed using a clamp meter or a multimeter. Start by measuring the current on the incoming power lines. Then, measure each circuit breaker’s current to ensure that they are within the acceptable range. Corrective action should be taken immediately if any current levels are outside of the acceptable range.

Resistance Testing

Resistance testing can be performed using a multimeter. Start by measuring the resistance across the main busbars of the MCC. Then, measure the resistance across each circuit breaker to ensure they are within the acceptable range. Corrective action should be taken immediately if any resistance levels are outside of the acceptable range.

Insulation Resistance Testing

Insulation resistance testing can be performed using a megohmmeter or an insulation tester. Start by measuring the insulation resistance across the main busbars of the MCC. Then, measure the insulation resistance across each circuit breaker to ensure they are within the acceptable range. Corrective action should be taken immediately if any insulation resistance levels exceed the acceptable range.

Cleaning and Lubrication

Cleaning Procedures

Regular cleaning of an MCC can help prevent the buildup of dust, debris, and other contaminants that can cause problems with the operation of the MCC. Start by removing any loose debris from the MCC enclosure. Then, wipe down the enclosure with a damp cloth or use an air compressor to blow out any remaining debris. Pay special attention to the ventilation system, which can become clogged with debris over time.

Lubrication Procedures

Lubrication of moving parts within an MCC can help prevent wear and tear and extend the life of the equipment. Start by identifying any moving parts within the MCC that require lubrication. Apply the appropriate lubricant to these parts according to the manufacturer’s recommendations. Take care not to over-lubricate, as this can lead to excess buildup and attract debris.

Documentation

Record Keeping

Documentation is essential for ensuring that preventative maintenance procedures are performed regularly and any issues are identified and addressed on time. Keep detailed records of all maintenance procedures, including inspections, testing, cleaning, and lubrication. This documentation can help identify trends and issues and provide a valuable reference for future maintenance.

Maintenance Logs

Maintain a detailed maintenance log for each MCC in your facility. This log should include information about the date of each maintenance procedure, who performed the procedure, and any issues or concerns that were identified. This log can help ensure that maintenance procedures are performed regularly and that any issues are identified and addressed promptly.

Repair Logs

In addition to maintenance logs, it is essential to maintain detailed repair logs for each MCC in your facility. This log should include information about any repairs performed, the repair date, who performed the repair, and any parts replaced. This log can help identify trends and issues over time and provide a valuable reference for future repairs.

Conclusion

Preventative maintenance is essential for the safe and efficient operation of MCCs. Following the checklist outlined in this blog post, industrial facility managers and maintenance personnel can ensure that their MCCs operate safely and efficiently. Regular maintenance can help prevent unexpected downtime, reduce repair costs, and extend the life of MCCs

If you’re looking for professional motor control panel maintenance and repair services, look no further than ECSKSA Electrical Care Services. Our team of experienced technicians has the expertise to keep your MCCs running safely and efficiently. Contact us today to learn more about our services and to schedule a consultation. Don’t wait until it’s too late, protect your investment and ensure the longevity of your motor control panels with ECSKSA.

Do you have a question in your mind? If so, make sure to fill out the form below!