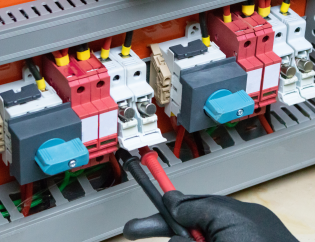

An electric junction box can be made from various materials, such as metal, plastic, or fiberglass, depending on the intended use and the environment in which it will be installed. It has different sizes, shapes, and configurations to accommodate different electrical connections.

The box has a removable lid or covers, allowing easy wiring and electrical components access. The lid is typically secured with screws or clips and may include a rubber gasket to prevent moisture and dust from entering.

Inside the junction box, you will find electrical terminals, connectors, and wiring. These components connect the electrical wiring from various sources, such as electrical appliances, lights, switches, and outlets. The junction box acts as a central point where all the electrical connections come together, making it easy to troubleshoot and repair any issues that may arise.

In addition to its protective and organizing functions, an electric junction box also serves as a safety device. It can prevent electrical fires and hazards by containing any electrical sparks or shorts that may occur. It also ensures compliance with electrical codes and regulations, which require electrical connections to be properly enclosed and protected.

What Does an Electrical Junction Box Do

An electrical junction box is a critical component in the electrical system that provides a safe, organized, and secure location for electrical connections and wiring components. It serves a variety of functions that are essential to the proper functioning of an electrical system, including:

- Housing electrical connections: The primary function of an electrical junction box is to house and protect electrical connections. The box provides a safe and secure location where electrical connections can be made between wires, cables, or devices.

- Protecting wiring and components: The junction box protects wiring and components from environmental elements like moisture, dust, and corrosion. This prevents damage to the wiring and components, ensuring that they remain in good working order and avoiding the risk of electrical hazards or fires.

- Organizing electrical connections: Electrical junction boxes help to organize electrical connections, which can be particularly important in complex systems with many connections. The box is a central location where all the electrical connections can be made and accessed, making it easy to troubleshoot and repair any issues that may arise.

- Preventing electrical hazards: An electrical junction box can help prevent electrical hazards by containing electrical sparks or shorts. This protects against the risk of electrical fires, electrical shock, or other hazards from exposed wiring.

- Ensuring compliance with electrical codes & regulations: Electrical codes and regulations require electrical connections to be properly enclosed and protected. Electrical junction boxes provide a means of compliance with these requirements, ensuring that electrical systems are safe and compliant with relevant regulations.

Learn more about our product: Distribution Panel Boards

Types of Electrical Junction Boxes

Several types of electrical junction boxes have unique characteristics that make them suitable for specific applications. The most common types of electrical junction boxes include:

1. Plastic junction boxes

These are made from high-quality plastic material and are lightweight, affordable, and easy to install. They are typically used in dry areas and are suitable for residential and commercial installations.

2. Metal junction boxes

These boxes are made from metal materials such as steel, aluminum, or copper. They are sturdy, durable, and suitable for indoor and outdoor use. They can be used in industrial and commercial settings.

3. Weatherproof junction boxes

These boxes are designed to withstand harsh weather conditions such as rain, snow, and extreme temperatures. They are typically made from aluminum, stainless steel, or PVC.

4. Underground junction boxes

These boxes are used to enclose electrical connections and wiring that are buried underground. They are designed to protect electrical connections from moisture and other environmental factors.

5. Hinged junction boxes

These boxes have a hinged lid that can be easily opened and closed. They are ideal for applications requiring frequent access, such as in electrical maintenance rooms or control panels.

6. Pull boxes

These are larger junction boxes used for pulling and splicing wires. They typically have a removable cover that allows easy access to the wiring.

7. Terminal junction boxes

These boxes are designed to house electrical terminal blocks, which are used to connect multiple wires. They are commonly used in control panels, switchgear, and other industrial applications.

Also Read: Role of Busbar in switchgear

Conclusion

In conclusion, electrical junction boxes are essential components of any electrical system. They provide a safe and secure location for electrical connections and wiring components, protect wiring and components from environmental factors, and prevent electrical hazards. Several types of junction boxes are available, including plastic, metal, weatherproof, underground, hinged, pull, and terminal, each with unique characteristics that make them suitable for specific applications. Choosing the right junction box is crucial to ensure a safe and efficient electrical installation. Proper installation, use, and maintenance of electrical junction boxes are essential for the safety and reliability of the electrical system.

FAQs

Q1. What is the purpose of an electrical junction box?

An electrical junction box is designed to house and protect electrical connections, prevent electrical hazards, organize electrical connections, and ensure compliance with electrical codes and regulations.

Q2. How do you choose the right electrical junction box?

The type of junction box used depends on the specific application and environment where it will be installed. Consider factors like the size and number of wires to be enclosed, the environment, and compliance with electrical codes and regulations.

Q3. How do you maintain an electrical junction box?

Regular inspection and maintenance are essential to ensure the safety and reliability of electrical junction boxes. Inspect for signs of damage, corrosion, or wear, and make repairs or replacements as needed.

Do you have a question in your mind? If so, make sure to fill out the form below!