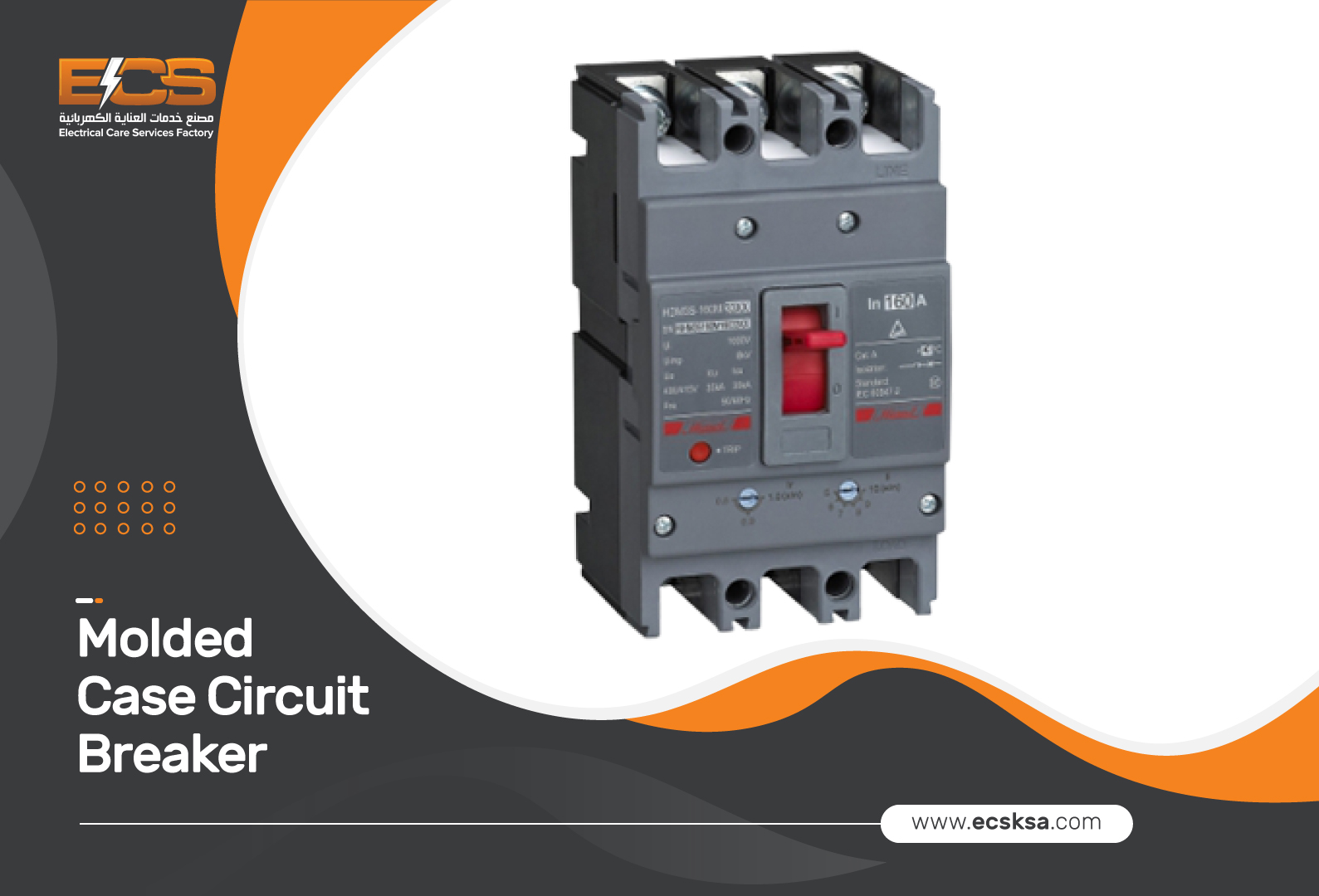

The term “molded case” refers to the circuit breaker’s outer casing made from a molded insulating material, usually thermoset plastic, which helps provide electrical insulation and mechanical protection. This casing is designed to be sturdy and durable and can help to prevent damage to the internal components of the MCCB.

Inside the molded case, the MCCB contains a set of current-carrying contacts that can be opened or closed manually or automatically to control the flow of electricity. When a fault occurs, such as an overload or short-circuit, the MCCB’s trip mechanism is activated, quickly opening the contacts and interrupting the current flow, thereby protecting the downstream equipment from damage.

MCCBs may also include additional features such as adjustable trip settings, ground fault protection, and auxiliary contacts for remote monitoring and control. They are commonly used in various applications, including commercial and industrial buildings, power generation and distribution systems, and motor control centers.

Also, Read: The Difference Between MCB AND MCCBs

Applications of Molded Case Circuit Breakers(MCCB)

Molded Case Circuit Breakers (MCCBs) are widely used in various applications where reliable and efficient protection against overcurrent and short-circuit faults is required. Some common applications of MCCBs include:

- Commercial and industrial buildings: MCCBs are often used as main circuit breakers for electrical panels in buildings, providing protection for power distribution systems, lighting, and other electrical equipment.

- Power generation and distribution: MCCBs protect transformers, generators, and other electrical equipment in power plants and substations.

- Motor control centers: MCCBs protect electric motors from overcurrent and short-circuit faults.

- Data centers: MCCBs protect servers, switches, and other equipment from overcurrent and short-circuit faults.

- Mining and heavy industry: MCCBs protect electrical equipment in harsh environments, such as underground mines and industrial settings.

- Marine and offshore applications: MCCBs protect electrical systems on ships and offshore oil rigs, where reliable protection against overcurrent and short-circuit faults is critical.

Overall, MCCBs are an essential component of many electrical systems, providing reliable protection against a range of electrical faults and helping to ensure equipment and systems safe and efficient operation.

Characteristics of Molded Case Circuit Breaker

Molded Case Circuit Breakers (MCCBs) has several important characteristics that make them suitable for a wide range of applications. Some of the key characteristics of MCCBs include the following:

- Current rating: MCCBs are available in a range of current ratings, typically from a few amps up to several hundred amps, making them suitable for use in various applications.

- Trip settings: MCCBs typically have adjustable trip settings, allowing the breaker to trip at a specific current level and protecting against overcurrent and short-circuit faults.

- Interrupting capacity: MCCBs are designed to interrupt the flow of current quickly and safely in the event of a fault, typically with an interrupting capacity of several thousand amps.

- Operating mechanism: MCCBs can be operated manually or automatically, depending on the specific application. Some MCCBs are designed to be tripped automatically in response to a fault, while others require manual intervention.

- Thermal and magnetic trip elements: MCCBs typically incorporate both thermal and magnetic trip elements, which allows the breaker to provide protection against both overloads and short circuits

- Compact design: MCCBs are designed to be compact and lightweight, making them easy to install and handle.

- Durability: MCCBs are typically constructed from high-quality materials designed to withstand a wide range of environmental and operating conditions.

Overall, these characteristics make MCCBs a highly versatile and reliable form of circuit protection, suitable for use in various electrical systems and applications.

Types of Molded Case Circuit Breakers

Several types of Molded Case Circuit Breakers (MCCBs) are available in the market today. The different types of MCCBs are designed to meet specific requirements and applications. Some of the most common types of MCCBs are:

1. Ground Fault Circuit Interrupter (GFCI) MCCBs

These MCCBs provide protection against ground faults, which occur when an electrical current flows through a ground path rather than through the intended circuit. GFCI MCCBs are commonly used in residential and commercial buildings, such as bathrooms and kitchens.

2. Arc Fault Circuit Interrupter (AFCI) MCCBs

These MCCBs provide protection against arc faults, which occur when an electrical current jumps from one conductor to another. AFCI MCCBs are commonly used in residential and commercial buildings, such as bedrooms and living rooms.

3. Electronic MCCBs

These are designed with advanced electronics to provide additional features, such as remote monitoring and control, and improved accuracy and reliability.

4. Thermal-magnetic MCCB

These MCCBs use both thermal and magnetic trip elements to provide protection against both overloads and short circuits

5. Compact MCCBs

These are designed to be smaller and more compact than standard MCCBs, making them suitable for space-constrained applications.

The specific type of MCCB used in a given application will depend on factors such as the required current rating, interrupting capacity, and other features needed for the application.

Conclusion

Molded Case Circuit Breakers (MCCBs) is an essential component of many electrical systems, providing reliable protection against a range of electrical faults and helping to ensure the safe and efficient operation of equipment and systems. Several types of MCCBs are available on the market, each designed to meet specific requirements and applications. Some of the most common types of MCCBs include standard MCCBs, high-performance MCCBs, GFCI MCCBs, AFCI MCCBs, electronic MCCBs, thermal-magnetic MCCBs, and compact MCCBs. The specific type of MCCB used in a given application will depend on factors such as the required current rating, interrupting capacity, and other features needed for the application. Overall, MCCBs are a highly versatile and reliable form of circuit protection, suitable for use in various electrical systems and applications.

FAQs

Q1: What is the difference between a molded case circuit breaker and a miniature circuit breaker?

Molded case circuit breakers (MCCBs) and miniature circuit breakers (MCBs) are circuit breakers used to protect electrical systems. The main difference between the two is the current rating and interrupting capacity. MCCBs are designed to handle higher currents and have a higher interrupting capacity than MCBs. MCBs are typically used in residential and light commercial applications, while MCCBs are used in industrial and heavy commercial applications.

Q2: What is the difference between a thermal-magnetic MCCB and an electronic MCCB?

Thermal-magnetic MCCBs use thermal and magnetic trip elements to protect against both overloads and short circuits. Electronic MCCBs, on the other hand, use advanced electronics to provide additional features, such as remote monitoring and control, improved accuracy and reliability, and additional protection functions. Electronic MCCBs are typically more expensive than thermal-magnetic MCCBs but offer enhanced functionality and flexibility.

Q3: How do I reset an MCCB after it trips?

To reset an MCCB after it trips, you must first identify and address the cause of the trip, such as an overload or short circuit. Once the cause of the trip has been addressed, you can reset the MCCB by moving the operating handle to the OFF position and then back to the ON position. It’s important to follow the manufacturer’s instructions for resetting the MCCB to ensure proper operation and safety.

Do you have a question in your mind? If so, make sure to fill out the form below!