How Busbar Works in Switchgear

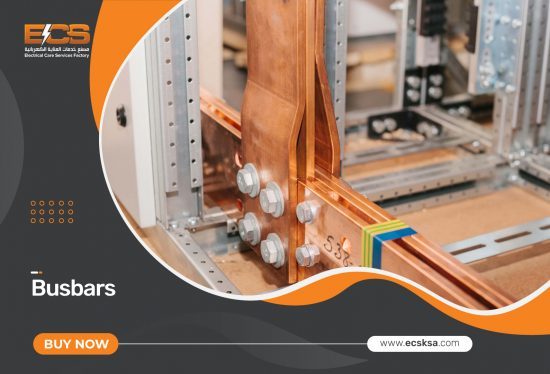

In a switchgear system, the busbar is responsible for distributing electrical power from a generator or transformer to various loads. It acts as a central hub, connecting multiple circuits and allowing for easy and efficient power distribution. Busbar can be made of materials such as copper or aluminium and are typically found in medium-voltage and high-voltage switchgear.

The distribution of electrical power through a busbar is done through a process called busbar tapping. This process involves connecting a tap conductor to the busbar, allowing power distribution to various loads. The tap conductor can also be disconnected when necessary, allowing for the isolation of specific circuits.

Materials Used for Busbar

Copper and aluminium are the most commonly used materials for busbar. Copper is known for its high conductivity, which makes it an ideal choice for busbar. It also has a high melting point, which makes it suitable for high-voltage applications. On the other hand, aluminium is a lightweight metal known for its good conductivity. It is typically used in low-voltage applications due to its lower melting point.

Applications of Busbar in Switchgear

Busbar are used in various applications, including power generation, transmission, and distribution systems. In power generation, busbar are used to distribute electrical power from generators to the transmission grid. In transmission systems, busbar distribute power from substations to various loads. In distribution systems, busbar are used to distribute power from substations to homes and businesses.

Advantages of Using Busbar in Switchgear

There are several advantages of using busbar in switchgear, including

- Increased efficiency: Power can be distributed more efficiently and effectively by using a single connection point for multiple circuits.

- Space-saving: Busbar take up less room in switchgear systems, which can be beneficial when space is limited.

- Cost-effective: Using busbar can be cost-effective as it reduces the need for multiple connection points.

Maintenance and Safety Considerations

Regular maintenance of busbar is crucial to ensure their proper functioning. This includes checking for signs of wear and tear, such as corrosion, and making repairs as necessary. Safety precautions, such as wearing protective gear and using the proper tools, should be taken when working with busbar.

Conclusion

In conclusion, busbar play a vital role in the efficient distribution and management of electrical power in switchgear systems. They act as a common connection point for multiple circuits, allowing power distribution from a single source to multiple loads. Busbar can be made of copper or aluminium and are used in various applications, including power generation, transmission, and distribution systems. With regular maintenance and proper safety precautions, busbar can help ensure a reliable and cost-effective power supply. As technology advances, we can expect new developments in busbar technology to make it more efficient, reliable and cost-effective in the future.

Contact ECSKSA today to learn more about how busbar can improve the efficiency of your switchgear system.

Do you have a question in your mind? If so, make sure to fill out the form below!