Types of Ring Main Unit

Ring Main Units (RMUs) are compact, air-insulated switchgear units used in medium voltage distribution networks. They are used for protection and control of power distribution systems in industrial and commercial settings. RMUs are available in different types based on their configuration, functionality, and application. Here are some of the most common types of Ring Main Units:

- Air-Insulated RMU: This type of RMU uses air as the primary insulation medium for its components. It is environmentally friendly, as it does not use any gases or oils that can potentially harm the environment. Air-insulated RMUs are typically used in indoor applications, such as in commercial and industrial buildings.

- Gas-Insulated RMU: This type of RMU uses sulfur hexafluoride (SF6) gas as the insulation medium for its components. SF6 gas is a highly efficient and reliable insulator that can withstand high voltage and current levels. Gas-insulated RMUs are typically used in outdoor applications, such as in substations or in areas where space is limited.

- Oil-Insulated RMU: This type of RMU uses mineral oil as the insulation medium for its components. Oil-insulated RMUs are typically used in areas where there is a risk of fire, such as in underground substations. They are also commonly used in rural areas where the power supply is unreliable.

Each type of RMU has its advantages and disadvantages, and the selection of the appropriate type depends on various factors such as the application, voltage levels, available space, and environmental considerations.

Components of Ring Main Unit

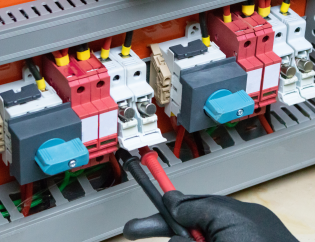

The components of the RMU include a metal enclosure, switchgear components, and control components. The metal enclosure is made of stainless steel or aluminum, protecting the switchgear and control components from external factors such as moisture, dust, and heat.

The switchgear components of the RMU include a circuit breaker, load break switch, earthing switch, and fuse switch. The circuit breaker is used to interrupt the flow of electricity in the event of an overload or a fault. The load break switch is used to isolate faulty sections of the network. The earthing switch provides a safe path for the flow of electricity in case of an earth fault. The fuse switch is used to protect the circuit from overloading.

The control components of the RMU include a protection relay, control panel, and SCADA (Supervisory Control And Data Acquisition) system. The protection relay is used to monitor the electrical network and to protect it from overloading and faults. The control panel controls the switchgear components of the RMU, while the SCADA system monitors and controls the RMU from a remote location.

Construction of Ring Main Unit

The construction of the RMU is a critical aspect of its functionality. The metal enclosure of the RMU is constructed using stainless steel or aluminum to protect the switchgear and control components from external factors such as moisture, dust, and heat.

The switchgear components of the RMU are designed to provide a reliable and safe electrical network. The circuit breaker, load break switch, earthing switch, and fuse switch are all high-quality materials that ensure their long life and reliability. The control components of the RMU are designed to provide a high level of control and monitoring, ensuring the safety and reliability of the electrical network.

Want to learn more about Ring Main Units and their applications in the electrical distribution system? Check out our product page for more information, and contact us to speak with our experts in the field.

Applications of Ring Main Unit

The Ring Main Unit is an essential component of the electrical distribution system and is used in various applications. Some of its typical applications include:

Residential areas:

RMUs are often used in residential areas to provide electricity to households. They are compact, easy to install, and require low maintenance, making them an ideal solution for residential spaces.

Commercial buildings:

RMUs are also used in commercial buildings such as shopping malls, hospitals, and office buildings to provide power distribution. They are often installed in the basement or on the ground floor of the building and are connected to the main electrical supply.

Industrial applications:

RMUs are used in various industrial applications such as manufacturing plants, refineries, and mining operations. They provide reliable and safe power distribution, ensuring uninterrupted functions and increased productivity.

Renewable energy systems:

RMUs are increasingly being used in renewable energy systems such as wind and solar power plants. They provide safe and efficient power distribution from renewable energy sources to the grid.

Advantages of Ring Main Unit

The RMU has several advantages, including:

- Compact size: The RMU is compact and requires less space than other types of switchgear.

- Easy maintenance: The RMU is easy to maintain and requires minimal maintenance.

- High reliability: The RMU is highly reliable and has a low failure rate, ensuring an uninterrupted power supply.

- Cost-effective: The RMU is cost-effective compared to other types of switchgear, making it a popular choice for power distribution systems.

Disadvantages of Ring Main Unit

The RMU also has some disadvantages, including:

- Limited power rating: The RMU has a little power rating compared to other types of switchgear, making it unsuitable for high power applications.

- Requires skilled personnel: The installation, operation, and maintenance of the RMU require qualified personnel, which can increase the overall cost.

- High initial cost: The initial price of the RMU is relatively high compared to other types of switchgear, which can be a deterrent for some users.

How to Select a Ring Main Unit

Selecting the right Ring Main Unit for your power distribution system is crucial to ensure reliable and efficient operations. Here are some factors to consider when selecting an RMU:

- Power rating: The power rating of the RMU should match the power requirements of your distribution system. Ensure that the RMU can handle the load capacity and the number of circuits required.

- Voltage rating: The voltage rating of the RMU should also be considered. Ensure that the RMU can handle the voltage of your electrical distribution system.

- Safety features: Look for RMUs with safety features such as interlocking mechanisms and earth fault protection to ensure safe operations.

- Maintenance requirements: Consider the maintenance requirements of the RMU. Look for RMUs that require low maintenance and are easy to service.

- Cost-effectiveness: Consider the cost-effectiveness of the RMU. Look for RMUs that provide a balance between cost and reliability.

Conclusion

The Ring Main Unit is an essential component of the electrical distribution system, providing safe and reliable power distribution. Its compact size, easy maintenance, high reliability, and cost-effectiveness make it a popular choice for power distribution systems. However, its limited power rating, requirement for skilled personnel, and high initial cost are some disadvantages that need to be considered before installing the RMU. When selecting an RMU, ensure that it matches the power and voltage requirements of your distribution system and has the necessary safety features and maintenance requirements. With technological advancements, the RMU is expected to play an even more critical role in the future of power distribution systems.

If you’re looking for a reliable and cost-effective solution for your power distribution system, consider installing a Ring Main Unit. Contact us today to learn more about our RMUs and how they can benefit your business.

Do you have a question in your mind? If so, make sure to fill out the form below!