Types of Magnetic Contactors

There are several types of magnetic contactors, including:

1. AC Magnetic Contactor

Designed to switch AC electrical circuits and typically used in HVAC systems, lighting control, and motor control applications.

2. DC Magnetic Contactor

Designed to switch DC electrical circuits and used in battery-powered systems, renewable energy systems, and other DC-powered applications.

3. Three-Pole Magnetic Contactor

Used for switching three-phase electrical circuits and commonly used in industrial motor control applications.

4. Four-Pole Magnetic Contactor

Similar to the three-pole contactor, but adds an additional switch to isolate the circuit and ensure safety.

5. Miniature Magnetic Contactor

A smaller version of the magnetic contactor, typically used in space-constrained applications and control panels.

6. High-Temperature Magnetic Contactor

Designed for use in high-temperature environments and used in applications such as furnaces, kilns, and other high-heat applications.

7. Thermal Overload Magnetic Contactor

It incorporates a thermal overload relay to protect against overloading and over-current conditions.

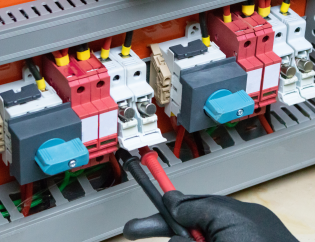

Application of Magnetic Contactors

Magnetic contractors have a wide range of applications in various industries, including:

- HVAC: Magnetic contactors are used to control the operation of air conditioning and heating systems.

- Motor control: Magnetic contactors are commonly used to switch high-power motors in industrial applications, such as pumps, conveyors, and fans.

- Lighting control: Magnetic contactors are used to switch lighting circuits in commercial and industrial buildings.

- Power distribution: Magnetic contactors are used in power distribution systems to switch large electrical loads, such as transformers and generators.

- Renewable energy systems: Magnetic contactors are used in wind turbines, solar panels, and other renewable energy systems to switch high-power electrical circuits.

- Elevators: Magnetic contactors are used in elevator control systems to switch the power to the elevator motor and control its operation.

- Automation systems: Magnetic contactors, such as robotics and control panels, are used in automation systems to switch electrical circuits and control equipment.

Advantages of Magnetic Contactors

There are several advantages of using magnetic contactors, including:

- Reliability: Magnetic contactors are designed to be highly reliable and durable, providing a long service life in demanding applications.

- Safety: Magnetic contactors provide a safe and controlled way to switch high power electrical circuits, reducing the risk of electrical shock and fire.

- Ease of Use: Magnetic contactors are simple to install and use, making them a popular choice for controlling electrical circuits in various applications.

- Cost-Effective: Magnetic contactors are a cost-effective solution for controlling high-power electrical circuits, providing a cost-effective alternative to other switch types.

- Versatility: Magnetic contactors are available in various sizes and configurations, making them suitable for various applications and environments.

- Power Handling: Magnetic contactors are designed to handle high-power electrical circuits, making them suitable for high-power applications such as motor control and power distribution.

- Protection: Magnetic contactors can be equipped with thermal overload relays and other protective features to provide additional protection against overloading and over-current conditions.

Conclusion

In conclusion, magnetic contactors are essential in many electrical systems and have numerous advantages over other switches. They are reliable, safe, easy to use, cost-effective, versatile, capable of handling high power and can be equipped with protection features. Magnetic contactors are commonly used in various applications, including HVAC, motor control, lighting control, power distribution, renewable energy systems, elevators, and automation systems. If you are in need of a reliable and effective solution for switching high-power electrical circuits, a magnetic contactor is a good option to consider.

Upgrade magnetic contactors with ECSKSA for improved reliability, safety, and cost-effectiveness. Contact our experts for a personalized consultation and find the perfect solution for your needs.

FAQs

1. What is a magnetic contactor used for?

A magnetic contactor switches high-power electrical circuits, such as motors, lighting, and heating systems. They provide a safe and reliable way to control electrical circuits and are commonly used in HVAC, motor control, lighting control, power distribution, renewable energy systems, elevators, and automation systems.

2. How does a magnetic contactor work?

A magnetic contactor consists of a coil and switch contacts. When the coil is energized, it creates a magnetic field that attracts an armature and closes the switch contacts. When the coil is de-energized, the switch opens.

3. Can magnetic contactors handle high-power electrical circuits?

Yes, Magnetic contactors are designed to handle high-power electrical circuits, making them suitable for motor control and power distribution applications.

Do you have a question in your mind? If so, make sure to fill out the form below!