What is a Pressure Switch

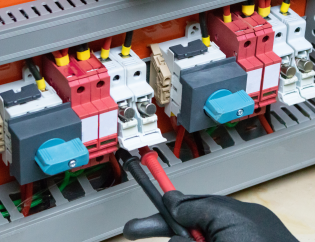

A pressure switch is an electrical component that is designed to control an electrical circuit based on the presence or absence of pressure. It typically contains a sensing element that responds to changes in pressure and a switch mechanism that activates or deactivates the electrical circuit.

When the pressure being monitored reaches a certain predetermined level, the pressure switch will close the circuit and allow current to flow. This can be used to activate a device, such as a pump or a motor, or to turn off a device, such as an air compressor or a heating system.

Pressure switches are used in a wide range of applications, such as in HVAC systems, hydraulic and pneumatic systems, water and air filtration systems, and more. They are available in various designs and configurations, including differential pressure switches, vacuum switches, and solid-state pressure switches.

How Does It Work

The specific working of a pressure switch can vary depending on its design and intended application, but the basic principle remains the same.

Typically, a pressure switch will have a sensing element, which can be a diaphragm, a piston, or a bellows, that responds to changes in pressure. This sensing element is usually connected to a set of contacts, which are normally open when no pressure is applied to the sensing element.

When the pressure being monitored reaches a certain predetermined level, the sensing element will move, causing the contacts to close and completing an electrical circuit. This circuit can connect various devices, such as pumps, motors, solenoid valves, alarms, or other control systems.

The pressure switch may also have an adjustment mechanism that allows the user to set the pressure level at which the switch will activate. This adjustment mechanism may involve turning a screw, adjusting a spring, or using other methods depending on the specific design of the pressure switch.

In some cases, the pressure switch may be combined with other components, such as relays or timers, to provide additional control and flexibility. Overall, the basic function of a pressure switch is to detect changes in pressure and use this information to control an electrical circuit or other devices.

Types Of Pressure Switches

There are several types of pressure switches, and the specific type used will depend on the application and requirements. Here are some of the most common types of pressure switches:

-

Electromechanical pressure switches

These are the most commonly used types of pressure switches. They work by using a diaphragm or piston to detect changes in pressure, activating or deactivating an electrical circuit. These switches are commonly used in HVAC systems, water and air filtration systems, and other similar applications.

-

Solid-state pressure switches

These switches use a solid-state sensor to detect changes in pressure rather than a mechanical mechanism. They are often more accurate and reliable than electromechanical switches and can be used in applications where vibration or shock may damage a mechanical switch.

-

Differential pressure switches

These switches are designed to detect the difference in pressure between two points in a system rather than a single pressure value. They are commonly used in HVAC systems, filters, and flow monitoring.

-

Vacuum pressure switches

These switches detect changes in vacuum or negative pressure rather than positive pressure. They are often used in vacuum pumps, packaging equipment, and other similar applications.

-

High-pressure switches

These switches are designed to detect and control high-pressure systems, such as hydraulic or pneumatic systems. They can be used to prevent overpressure and protect equipment from damage.

-

Low-pressure switches

These switches are designed to detect and control low-pressure systems, such as air or gas flow in HVAC systems or industrial applications. They can be used to prevent pressure and ensure that equipment is functioning properly.

Overall, the type of pressure switch used will depend on the specific application and the requirements of the system being monitored or controlled.

Conclusion

In conclusion, pressure switches are important electrical components that play a crucial role in monitoring and controlling pressure in various systems and applications. They work by detecting changes in pressure and using this information to activate or deactivate an electrical circuit or other devices, such as pumps, motors, or alarms. With different types of pressure switches available, including electromechanical, solid-state, differential, vacuum, high-pressure, and low-pressure switches, they can be used in a wide range of applications, from HVAC and water filtration systems to hydraulic and pneumatic systems. Ultimately, the selection of a specific pressure switch will depend on the system’s monitoring or control requirements.

In ECSKSA, Learn more about the HVAC control panels.

FAQs

1. What is the maximum pressure rating for a pressure switch?

The maximum pressure rating for a pressure switch varies depending on the specific design and application. Some switches can handle pressures up to several thousand PSI, while others may be designed for lower pressure ranges.

2. What is the difference between a single-pole and double-pole pressure switch?

A single-pole pressure switch has one set of contacts, while a double-pole pressure switch has two sets of contacts. The double-pole switch provides an additional level of safety by providing redundant contacts for switching the electrical load.

3. Can a pressure switch be used for both air and water applications?

Some pressure switches are designed for use with both air and water, while others are only designed for one or the other. It’s important to check the specifications of the pressure switch to ensure it is compatible with the intended application.